Cost is a fundamental consideration in the chooseion of structural frame material and form, which is a key early decision in the design process. This chooseion should be based on project specific costings, and the challenge to the cost consultant is to recognise and reconcile fluctuations in material prices in relation to returned tender price data all in the context of limited available design information during early estimates.

Low rise and short span buildings

Low rise buildings with a regular, short span structural grid are typical features of business park offices and teaching facilities. A key feature of these buildings is flexibility, particularly for speculative business park developments that need to appeal to as many potential occupiers as possible.

The buildings often need to be easily subdivided into smaller units and have large floorplates, typically are two to four storeys and have floor-to-floor heights of 3.75-4m. These buildings will typically have a uniform grid of 6-9m that provides largely column-free space and relatively high floor-to-floor heights.

The lack of complex steel structures needed to construct the regular grid contributes to keeping the average steel frame weight down, typically 50-60kg/m2 including fittings, but this category can cover a lot of building types and functions. This central assumption therefore needs to be reviewed with the design team. Due to the low rise nature of these buildings, the fire protection requirements are not as onerous as for high rise developments and 30-60 minute fire protection would be considered standard.

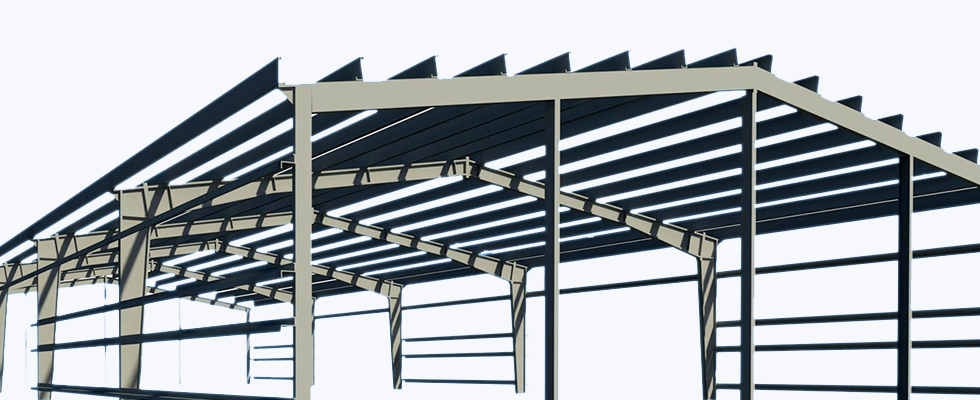

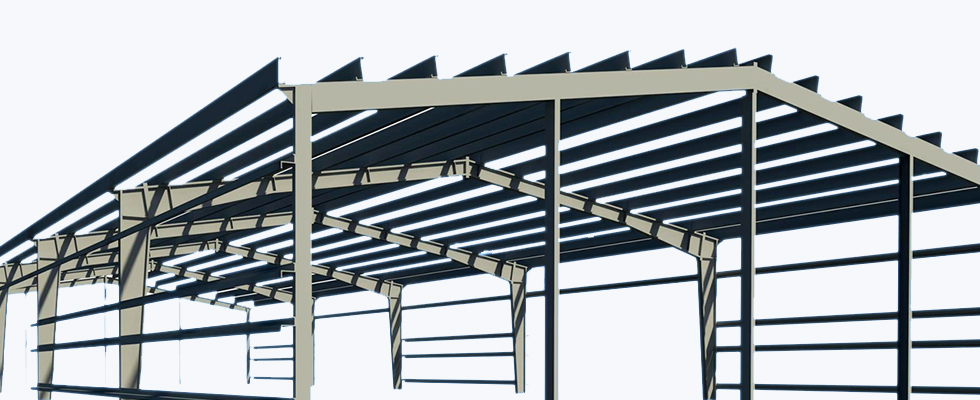

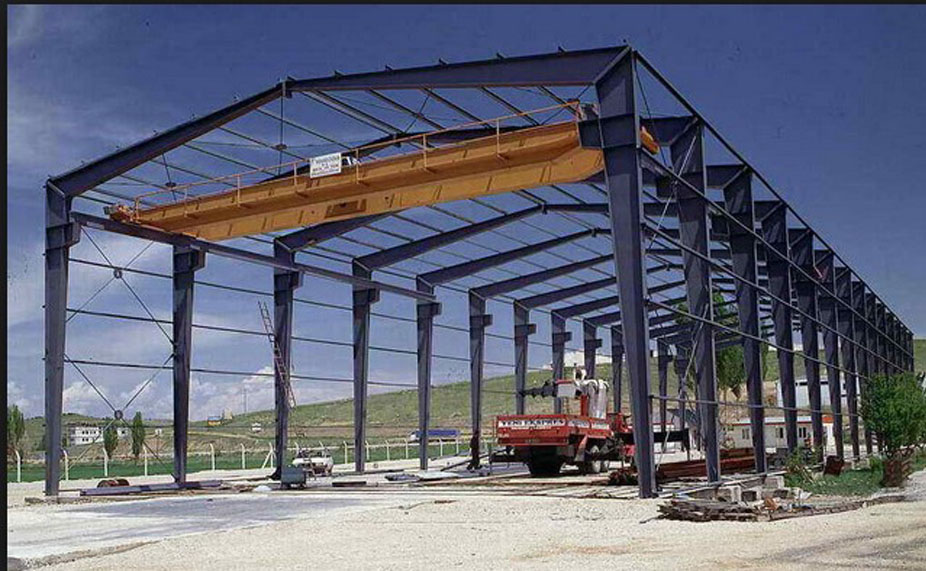

Industrial buildings

Industrial buildings can cover a range of uses, including warehouses, non-food retail, science parks and distribution centres. The most common building form is a single storey warehouse with varying proportions of office space on a first floor mezzanine level. The traditional structural frame for an industrial building is a steel portal frame, as flexibility of the internal space is a priority, necessitating regular column spacings and long spans for a clear internal area.

There can be variants on the standard frame design, however. For example, a steel portal frame incorporating northlights would need consideration when adjusting the standard cost ranges. The use of a northlight frame can increase the frame cost by as much as 30%.

Fire protection requirements may also be considered as part of industrial building frame costs. The most common situation in which fire protection is required in single storey buildings is where it is necessary to satisfy boundary conditions; this is a project-specific factor that will need some liaison with the design team. Generally however, single storey buildings do not require fire protection.

Another key factor in determining the frame cost of industrial buildings is the storey height of the warehouse space. While the gross internal floor area may be the same, the weight of the steel frame of a high eaves, single storey industrial building will be higher than for a low eaves building, resulting in a higher overall frame cost per m² GIFA.

Typical structural steel frame weights for low eaves buildings (6-8m high) are about 30-40kg/m² overall of GIFA, including fittings and about 40-50kg/m² for high eaves buildings (10-13m high). However, ranges for high eaves buildings are generally wider than for low eaves buildings as they can have a much higher proportion of upper floor areas, across as many as 3 mezzanine levels; the frame rates for these buildings therefore need to be looked at carefully on an individual basis.